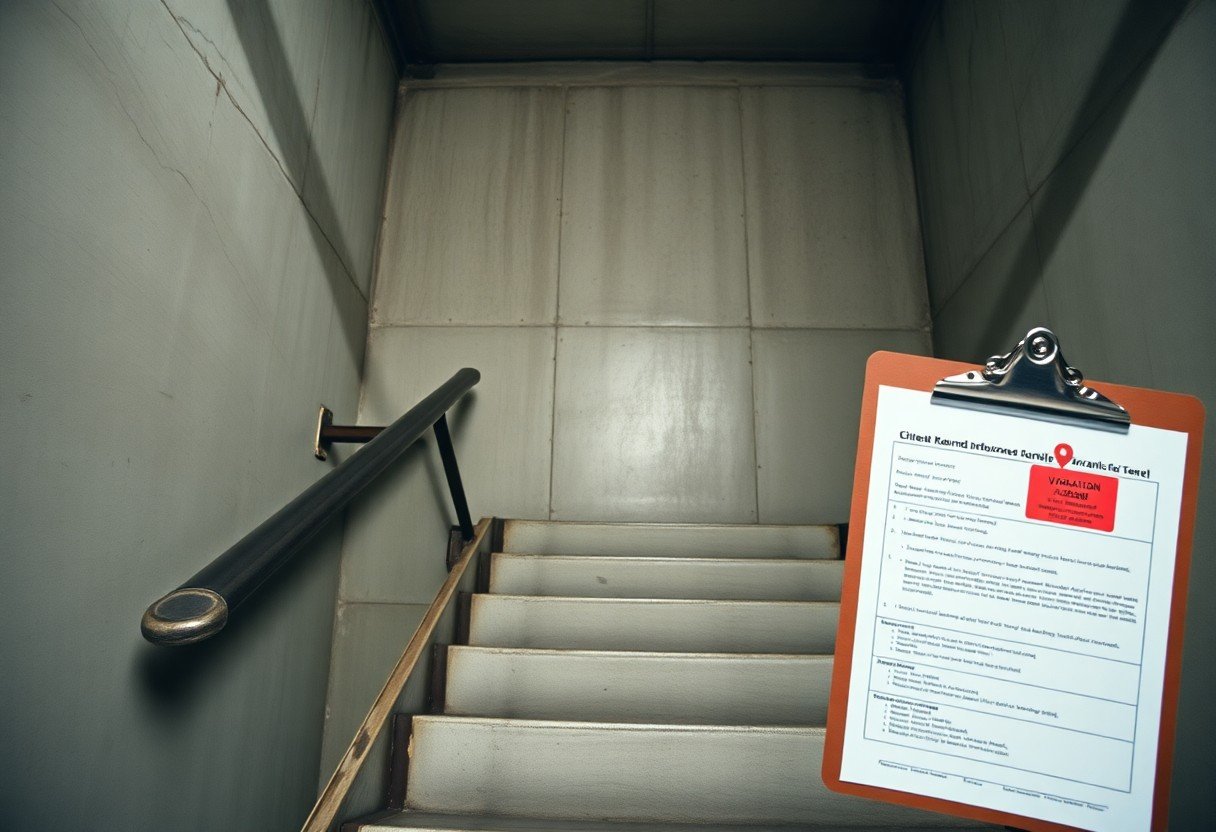

Many stair-related injuries happen when handrails are absent or improperly installed; you need to understand the applicable building codes, inspection criteria, and documentation practices to reduce risk and liability. This post explains how to evaluate handrail design, interpret code language, and create clear inspection and maintenance records for your projects.

Key Takeaways:

- Ensure continuous, graspable handrails on both sides where required; meet height (typically 34-38 in) and extension standards and provide proper clearances.

- Verify and cite applicable codes (local amendments, IBC, ADA) when evaluating noncompliance such as missing rails, improper height, or interrupted runs.

- Document falls and hazards thoroughly with dated photos, exact measurements, witness statements, and recent maintenance records.

- Prioritize corrective actions-repair or install handrails, add non-slip treads, improve lighting and nosing visibility-and log completion with dates and contractors.

- Maintain formal inspection and incident records for liability and insurance: inspection reports, corrective-action logs, code citations, and invoices for repairs.

Overview of Staircase Falls

You deal with stair-related incidents more often than you think: design defects, missing or non-graspable handrails, and code noncompliance (handrail height 34-38 in, riser max 7 3/4 in, tread min 10 in) create predictable failure points. Inspecting for those measurable factors-riser variation over 3/16 in, gaps in handrail continuity, or grab-size outside 1.25-2 in-lets you prioritize fixes that immediately lower trip and slip opportunities.

Common Causes

Uneven risers and shallow treads are primary contributors, with riser variations greater than 3/16 in and treads under 10 in producing missteps. You also encounter handrails set too low or with non-graspable profiles, inadequate lighting, slippery nosing, and cluttered landings; each of these failures aligns with specific code parameters you can measure and document during inspections.

Impact on Safety

Falls on stairs disproportionately affect older adults-about one in four people 65+ fall each year-and generate substantial healthcare burden; in the U.S. those falls resulted in roughly 3 million emergency visits and $50 billion in medical costs in recent years. When you ignore design nonconformities, you increase likelihood of fractures, head injuries, and liability claims tied to measurable code violations.

Digging deeper, you’ll find that continuous, graspable handrails at 34-38 in and consistent riser/tread geometry cut error rates because they give users predictable hand and foot placement. For example, replacing a non-graspable square rail with a 1.5 in circular rail and correcting a 1/2 in riser variance typically resolves recurring trip reports; documenting those before-and-after measurements strengthens repair justifications and risk mitigation for owners and operators.

Importance of Handrails

When you evaluate stair safety, handrails are a first-line defense: codes like IBC and ADA set handrail height at 34-38 inches from the nosing, and guards often require 42 inches, so your measurements directly affect compliance. For high-traffic or healthcare stairs you should provide rails on both sides; inspections should verify continuous graspability, secure anchorage, and unobstructed 1.5-inch clearance from the wall to prevent snagging and failed grips.

Design Standards

IBC and ADA specify 34-38 inch handrail heights and a minimum 1.5-inch wall clearance, so you should measure from the stair nosing. Circular grips must be 1.25-2 inches diameter; non-circular profiles require a 4-6.25 inch perimeter and a maximum 2.25 inch cross-section. Continuous gripping, returned ends or safety terminations, and 12-inch extensions at top and bottom are standard; you should also space supports typically every 4-6 feet to control deflection and meet load expectations.

Material Considerations

Material choice dictates longevity and maintenance: you’ll use 304 stainless for most interiors, upgrading to 316 in coastal or pool environments for superior chloride resistance. Aluminum gives light-weight, powder-coated options for lower maintenance; wood offers warmth but needs sealed finishes and fasteners rated for outdoor exposure. For slippery conditions, choose textured or knurled grips and plan annual inspections and finish touch-ups every 5-10 years.

For demanding installations you should specify stainless fasteners and isolation gaskets to avoid galvanic corrosion when mixing materials; for example, pair 316 stainless rail with stainless anchors in coastal projects. Use epoxy-set anchors or through-bolts for concrete to achieve required pull-out values, and design post spacing and rail sections to limit deflection under service loads. Finally, factor finish lifecycles-powder coat often lasts 10-15 years in mild climates, while marine-grade stainless retains appearance far longer with minimal upkeep.

Building Code Compliance

When you evaluate stair compliance, focus on the measurable minimums: handrails 34-38 in above tread nosing, guards 42 in, max riser 7 in and min tread 11 in, with baluster openings ≤4 in. Cross-check the adopted code edition and local amendments using the guide OSHA & IBC Industrial & Commercial Stair Code … to confirm which requirements apply to your project.

Local and National Codes

Your project will be governed by the national model (IBC/OSHA) plus whatever state or municipal amendments are adopted; many jurisdictions still reference the 2015 or 2018 IBC while others have moved to 2021 with stricter accessibility or slip-resistance rules. Verify the adopted edition, any state supplements, required permits, and inspection intervals before finalizing rail height, nosing detail, or material specs.

Common Violations

You commonly see handrails outside the 34-38 in range, non-continuous grips, missing returns, baluster spacing greater than 4 in, open risers exceeding allowed openings, treads under 11 in, and poor slip resistance on nosings-issues that show up on routine inspections and site audits. When you inspect, measure dimensions, check grip profile (1¼-2 in typical), and test surface traction.

Fixes usually include installing a continuous handrail with proper returns, adjusting rail height into the 34-38 in band, adding intermediate posts or anchors to limit deflection, closing riser gaps, and upgrading nosings to a higher coefficient of friction; document pre/post measurements, photos, and any load or pull tests to prove the remediation met code and reduce liability exposure.

Documentation Requirements

Store documentation in a centralized digital system with date-stamped photos, annotated diagrams and searchable fields so you can pull a history for any stair by ID. Include inspection checklists, repair invoices and manufacturer specs, plus access logs and a consistent naming convention. Industry practice is to retain these records at least five years to support maintenance cycles, regulatory reviews and liability inquiries.

Inspection Records

Schedule visual checks monthly in high-traffic areas and quarterly elsewhere, with a hands-on full inspection annually. When you record inspections note handrail height (34-38 in), gripping diameter (1.25-2 in), projection, fastener torque, splices, corrosion and surface wear. Capture GPS or stair ID, inspector name, photos and corrective deadlines; if a measurement falls outside code, tag the rail out and log remediation within 48-72 hours.

Incident Reports

After a fall or near miss secure the area, photograph the condition from multiple angles and collect witness statements within 24 hours. Your incident report should list exact location, time, injuries, environmental conditions, prior inspection dates and immediate corrective steps. Submit a preliminary report to safety leadership within 24 hours and attach supporting files so claims and audits proceed without delay.

Use a standardized incident form with checkboxes and narrative fields, attach at least three photos (overview, detail, context), and preserve the affected handrail for inspection-tag and quarantine it if feasible. You should record chain-of-custody for any removed parts, log contractor actions, and retain incident files for at least five years or the applicable statute-of-limitations period; close the loop with verification photos and dates to maintain a defensible audit trail.

Risk Mitigation Strategies

Layer your approach: enforce IBC/ADA-compliant handrail geometry (34-38 in height, 1.25-2 in grip diameter, 1.5 in clearance) and design for 200 lbf concentrated loads, schedule monthly inspections with documented repairs, prioritize high-traffic staircases using incident rates per 10,000 users, and fund targeted retrofits where data shows repeat failures.

Maintenance Practices

Inspect handrails monthly with a checklist for anchors, splices, grip continuity and corrosion; torque fasteners to manufacturer values, retain torque logs, and replace bent or fatigued sections within 5-7 years or earlier if load testing fails. Use stainless or hot-dip galvanized anchors in corrosive environments and archive photos and inspector signatures for audits.

User Education

Train staff and frequent users with a 20-30 minute module on safe stair technique, hazard spotting, and prompt reporting; require initial training within the first week and quarterly refreshers, install pictogram signage at each stair entry, and mandate reporting of any loosened rail within 24 hours so you close the response loop.

Set measurable targets: 90% training completion, median repair time under 72 hours, and escalation for unresolved defects after 48 hours; deploy QR-coded maintenance forms, require before/after photos on tickets, and review stair incident metrics monthly so you can demonstrate program impact and reallocate resources to persistent hotspots.

Case Studies

You can see patterns where missing documentation, incorrect handrail heights, and inadequate load capacity directly increased incident rates; the following cases provide measured data, remediation costs, and enforcement outcomes to guide your risk assessments.

- Case 1 – 2019 suburban apartment block: 7 reported falls in 24 months; measured handrail height 820 mm (code 900 mm); lateral deflection 40 mm under 200 N (acceptable ≤25 mm); inspection interval averaged 5 years; remediation cost $45,000; municipal citation issued.

- Case 2 – 2021 university library: 2 fractures from stair slips; missing continuous handrail on an 18 m flight; grip diameter 50 mm (recommended 30-45 mm); retrofit cost $12,500; absence of as-built drawings delayed repairs 4 months.

- Case 3 – 2018 transit station: 15 incidents over 5 years prompting inspection; handrail failed a 500 N point load (required ≥1,000 N); temporary closure for 3 weeks; structural retrofit $220,000; inspection logs incomplete for 60% of entries.

- Case 4 – 2020 retail mall: 3 serious injuries linked to variable rail height (variation ±70 mm across flights) and slippery nosing; vendor-installed rails lacked end returns; insurer recorded a 35% premium increase post-incident; retrofit $95,000.

- Case 5 – 2016 historic theater: multiple near-misses, no reported injuries; rail anchorage into plaster failed after 3 months under routine use; preservation constraints extended remediation 9 months; stainless-steel anchor retrofit $8,200; full documentation created post-fix.

Notable Incidents

You should pay attention to the transit station failure where a 500 N load-test collapse led to a 3-week closure and $220,000 repair bill, and the apartment block with 7 falls over two years tied to a 80 mm shortfall in rail height-both show how measurable code deviations convert to operational disruption and direct costs.

Lessons Learned

You will find that consistent measurement (height, grip diameter, deflection), routine load testing, and preserved inspection records directly reduce incidents, lower retrofit costs, and speed regulatory approval when issues arise.

In practice you should implement an inspection checklist that specifies handrail height tolerance ±10 mm, grip diameter range 30-45 mm, and a periodic load test at ≥1,000 N for public stairs; maintain digital, timestamped photos and retain records for at least 10 years; prioritize continuous rails on flights over 1.2 m and mandate annual inspections in high-traffic facilities to cut incident frequency and long-term liability.

Final Words

Upon reflecting, you should prioritize consistent handrail installation, compliance with local codes, and thorough documentation to reduce staircase fall risk. Ensure your handrails meet height, graspability, and continuity requirements, address code discrepancies promptly, keep clear records of inspections and repairs, and train staff or occupants so corrective actions are timely and verifiable.

FAQ

Q: What handrail specifications reduce fall risk on staircases?

A: Handrails should be 34-38 inches above the nosing measured vertically, provide a 1.25-2 inch round-grip equivalent for graspability, and have 1.5 inches minimum clearance from the wall. Handrails must be continuous along the full length of the stair run, include extensions at top and bottom (typically 12 inches beyond the top and a tread depth at the bottom), return to a wall or post or terminate in an acceptable fitting, and be mounted to resist a 200-pound concentrated load in any direction. Where stairs are wider than 44 inches, handrails on both sides are required; guards at open sides must be at least 42 inches high with baluster openings preventing a 4-inch sphere passage.

Q: What code deficiencies are most commonly cited during stair inspections?

A: Inspectors commonly cite missing or non-continuous handrails, handrails installed outside the required height range, non-graspable profiles (flat or oversized rails), inadequate clearances from walls or obstructions, handrail ends not returned, open risers exceeding allowable limits, guard heights below 42 inches, baluster spacing exceeding a 4-inch sphere rule, and handrails or guards not meeting structural load requirements. Documentation or lack of manufacturer data for prefabricated systems and field-installed incorrect mounting hardware are also frequent violations.

Q: What documentation should be provided to demonstrate compliance for permitting and inspections?

A: Provide scaled drawings showing plan and elevation views of stairs and handrails with dimensions (rail height, clearance, extensions, baluster spacing), cross-sections of mounting details, material and finish specifications, manufacturer datasheets for prefabricated handrail systems, structural calculations or load test reports for nonstandard attachments, product listings/certifications, photos of installed conditions, and code references or notes indicating applicable editions and sections. For alternate designs, include an engineering memo or stamped drawings showing equivalency and any test results; submit in PDF form with a cover sheet identifying the project and the approving authority.

Q: How can I retrofit an existing staircase to correct handrail and guard issues without full reconstruction?

A: Typical retrofits include adding surface-mounted or wall-mounted secondary handrails to achieve required height or both-side provisions, installing continuous rail adapters or returns to eliminate free ends, attaching surface-mounted reinforcing plates or blocking behind finishes to upgrade mounting strength, fitting infill panels, glass or metal screens to close oversized baluster openings, adding tread-edge nosings or riser inserts for open risers, and replacing non-graspable rails with code-compliant profiles. Choose materials compatible with the substrate, verify anchorage capacity, and document changes with as-built sketches and load calculations when altering structural attachments.

Q: When is an alternate method or variance needed and how is it approved?

A: A variance or alternate method is required when strict code compliance is impractical due to historic preservation, unusual site constraints, or when a proposed design differs from prescriptive code but offers equivalent safety. Prepare an alternate design package showing engineering analysis, test data or full-scale mock-ups, risk-mitigation measures, and a comparison demonstrating equivalent or superior safety. Submit the package to the authority having jurisdiction (AHJ) or building official; obtain written approval or a formal variance before construction or occupancy. Coordinate early with the AHJ to identify required submittal content and any conditions of approval.